Trapezoidal Grooving

The Goal

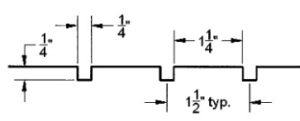

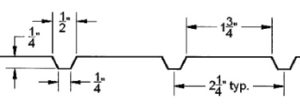

Although standard square grooving has proven its effectiveness year in and year out in practically eliminating hydroplaning accidents in the US, there are potential areas of improvement for square grooves. Although trapezoidal grooving has been employed in the past, budget constraints have limited its full potential. Not anymore. Working in conjunction with the FAA, Cardinal has developed a more efficient method for installing trapezoid shaped grooves at a price comparable to standard square shaped grooves. The diagram below shows the specifications of both standard and trapezoid grooves.

- Standard

- Trapezoid

The Benefits

In evaluating the benefits of any new method, it must first be compared to the previous standard it is looking to replace. Where grooving is involved, the starting point is the coefficient of friction. The results indicate that trapezoidal grooving is at least comparable to and/or better than standard square shaped grooves.

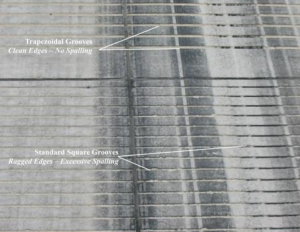

The advantages of a trapezoid shaped groove versus a square groove manifest themselves in several ways. Because of the oblique angle the aircraft tire encounters instead of a square angle, there is less tire wear which of course results in less rubber buildup. Because the reduced rubber buildup necessitates less cleaning, you should expect to see longer pavement life.

This oblique angle also results in greater structural integrity, meaning greatly reduced edge chipping (in concrete) and substantially less groove shoving or closing (in asphalt).

Lastly, a trapezoid is a much more efficient water carrying channel than a square groove resulting in much faster runway drainage vis-à-vis regular grooves.